Safe

Fast

Accurate

Cost-effective

Custom-BUILT

Advanced software

OneScreen – Oncology & TPN: Precision Compounding

Comprehensive Solutions for Chemotherapy and Parenteral Nutrition

OneScreen Onco

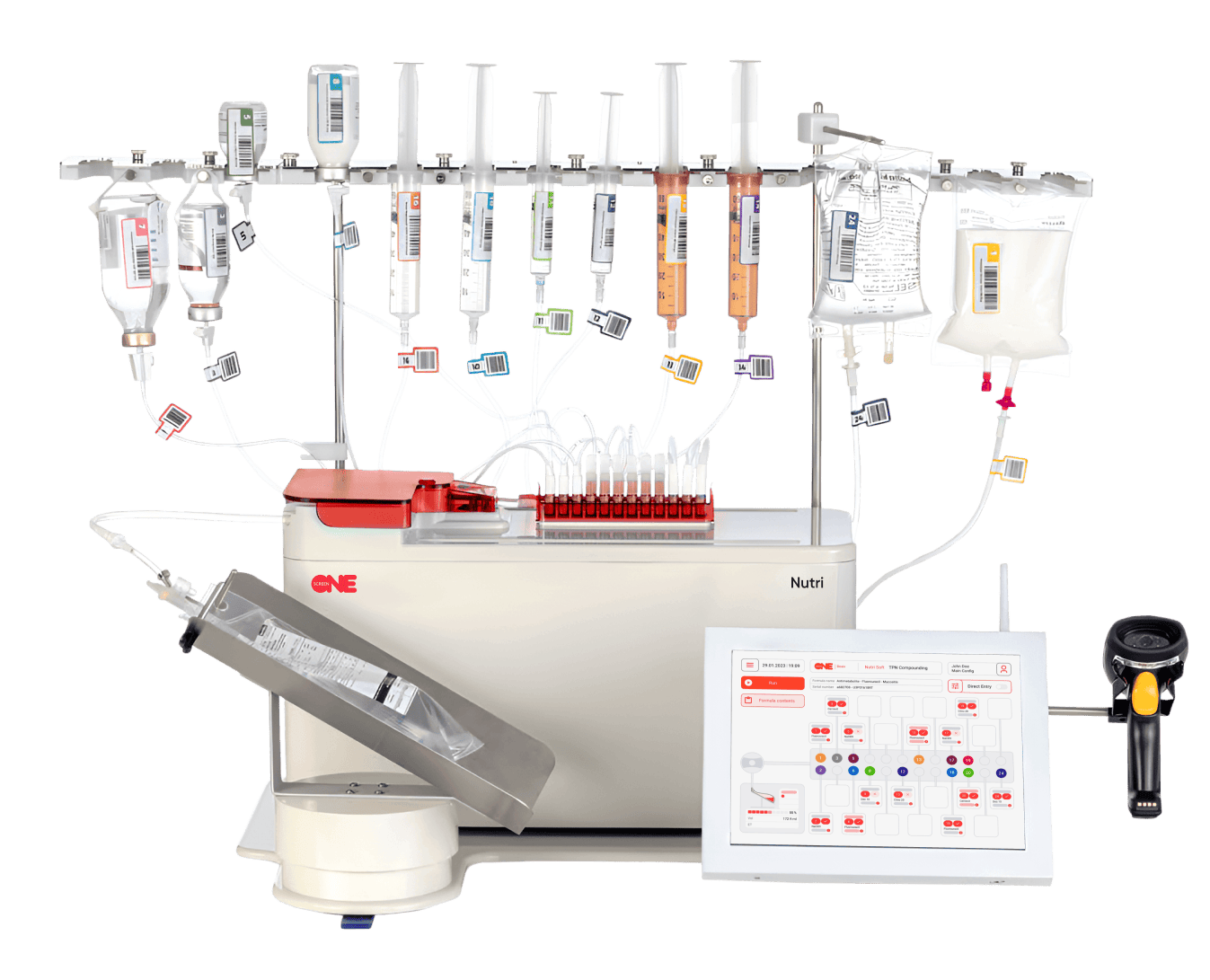

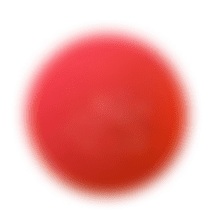

OneScreen Nutri

OneScreen Turnkey Solutions

- Innovative and cost-effective IV chemotherapy compounding solution

- Accuracy

- Traceability

- Easy and safe operation

- Cost-effective TPN compounding solution

- Mixing 24 different ingredients capacity

- Rapid and precise compounding

- Microbiological quality

- Prefabricated chemotherapy unit

- Cost-effective turnkey solution for quality oncology care

OneScreen

Eng

Patient Safety

- Biosafety compliance

- Dosage accuracy

- Controlled workflow from the order entry till the patient

Error Elimination

- Ultimate security features prevent human errors

- Double-stage final container labelling

- Visual drug recognition

- Barcode verification

Accuracy

- Precise volumetrical delivery

- Instant gravimetrical control

- Overdose prevention

- Dose verification

Operator Safety

- Prevention of hazardous drug exposure

- Prevention of hazardous drug needle-based injuries

- Closed system disposables

Traceability

- Traceable workflow from order entry to bed-site for every single patient dose and user steps

- Advanced drug/container inventory management each with a unique barcode

Microbiological Safety

- Biosafety cabinet

- Sterile closed system disposables

OneScreen Solutions Added Value

Cost-effectiveness

- Reduced drugs waste

- More productive staff

- Faster order preparation

- Greater number of orders per day

Prevents

Enhances

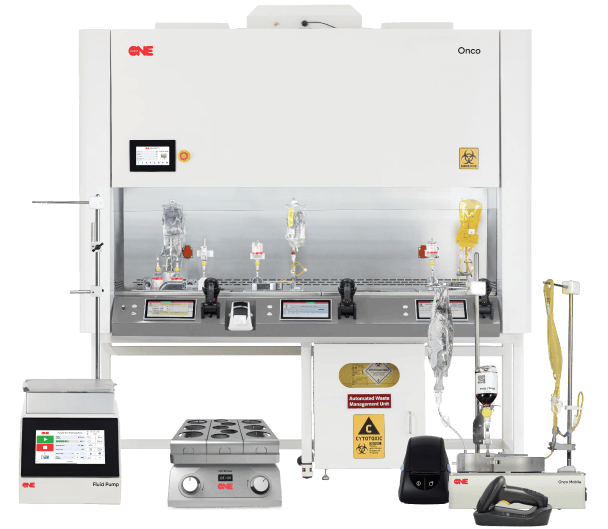

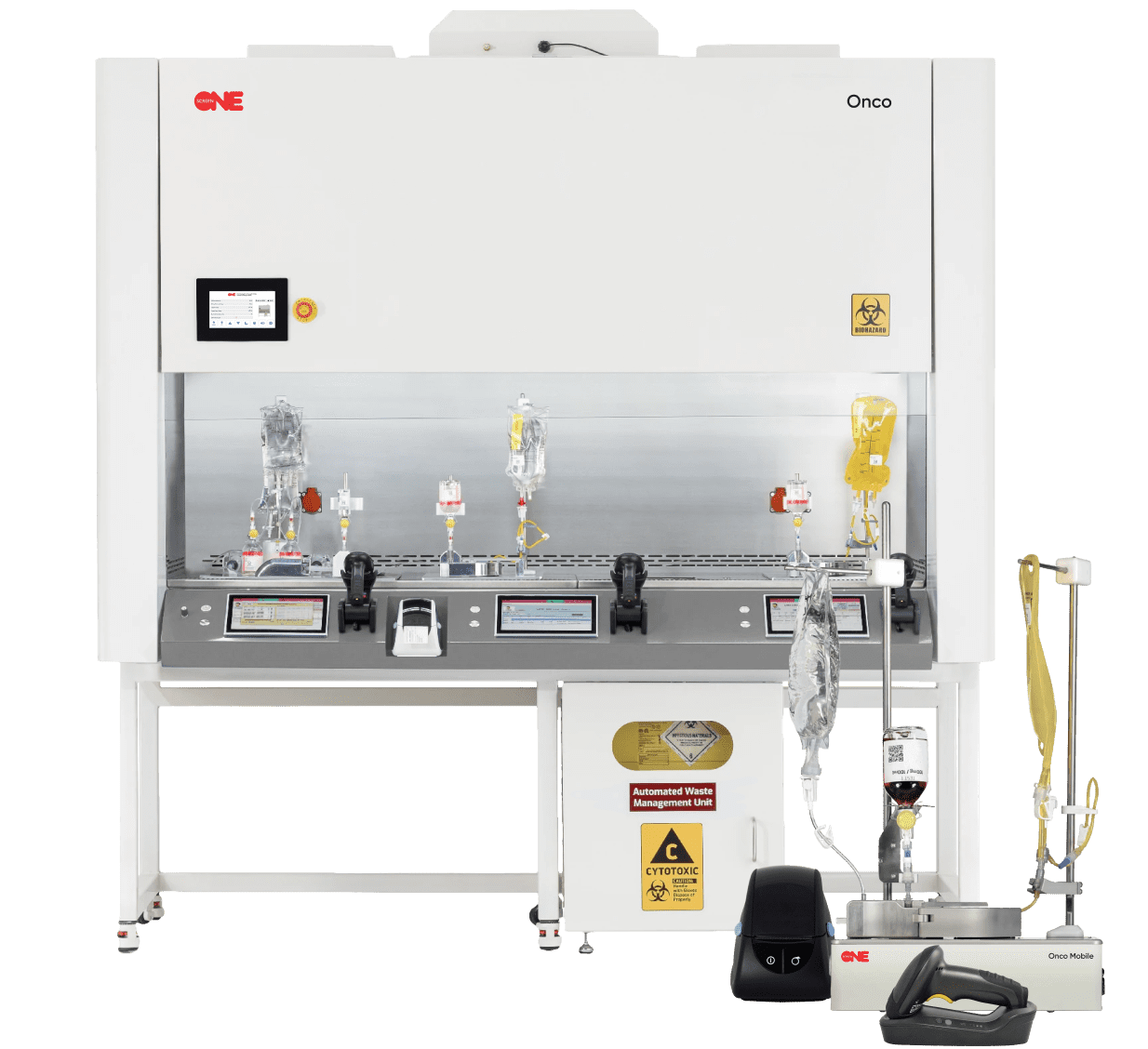

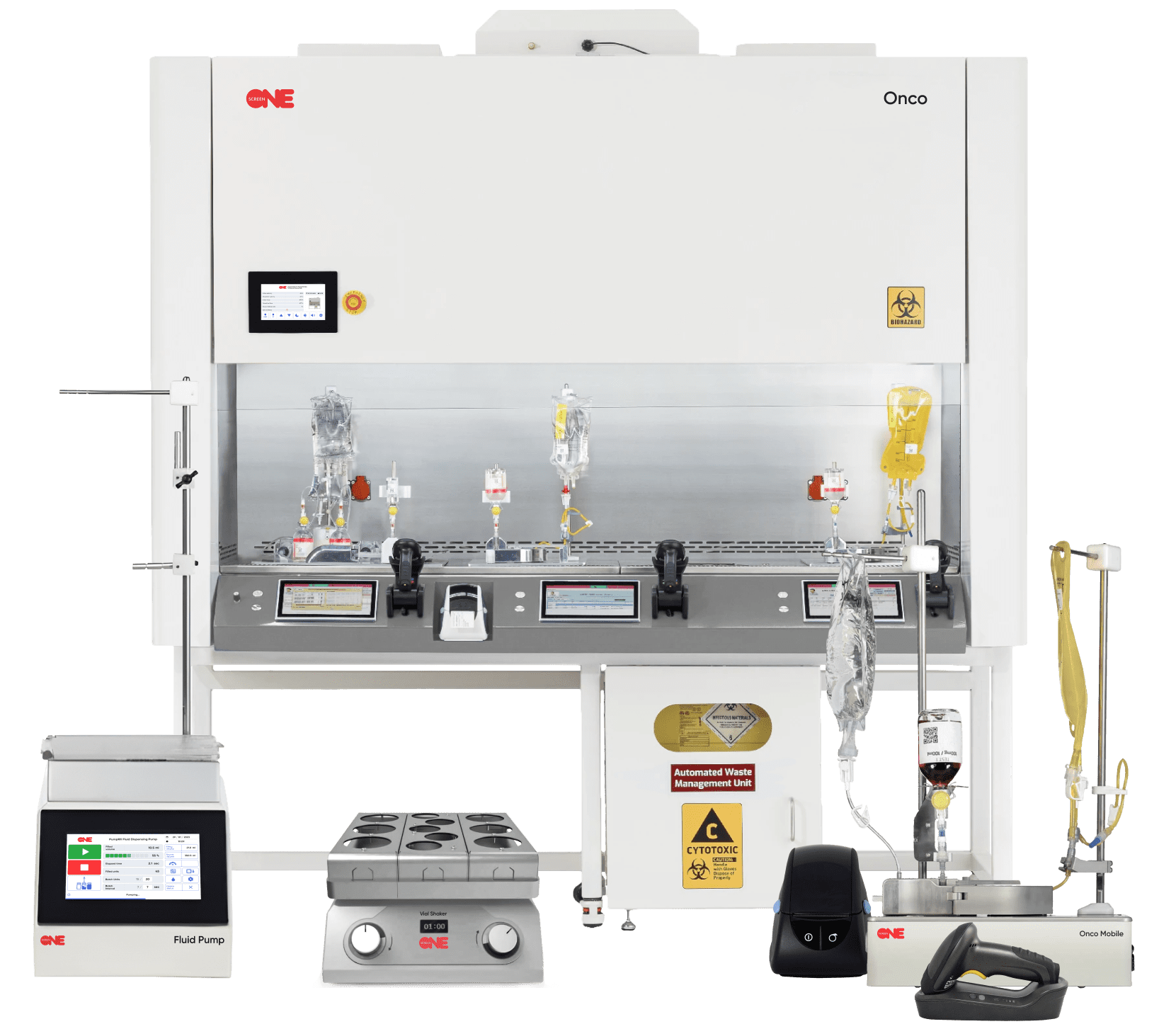

OneScreen Onco

Safe and Smart Technology

Safe and Smart Technology

Cost-effective innovative IV chemotherapy compounding solutions providing accurate dosing for patient safety and protecting operators and environment from the negative impact of hazardous drugs

- Ordering Errors

- Patient Safety

- Compounding Errors

- Traceability

- Manual Addition

- Workflow Speed

- Drug Waste

- Flexibility

- Needle-Based Injurie

- Compliance

- UV Light Effects

- ROI

- Touch-Contamination

- Quality Assurance

Compounding System

Fluid Pump

Mobile Compounding

System

System

Smart Solution for Vial Shaking

OneScreen Software Solution for Chemotherapy unit

Chemotherapy Workflow Management Software

- Help hospital staff manage IV chemotherapy workflow

- Enhances medication safety

- Enhances efficiency

- Enhances traceability from ordering to administration

Filling IV/EVA bags

Filling syringes

Filling elastomeric infusion pumps

Reconstituting vials

Filling oral syringes

Small footprint

Plug&Play

Timer adjustment

Your Smart Assistant

OneScreen Fluid Pump

- Reduces the workload

- Increases efficiency of various fluid dispensing operations

- Offers repeatable accuracy

Simplify the fluid dispensing operations:

OneScreen Vial Shaker

Smart Solution for Vial Shaking

Smart Solution for Vial Shaking

- Shaking up to 27 vials simultaneously

- Shaking speed adjustment

- 3 replaceable vial housing areas

- Compatible with vials of different diameters

Prevents

Enhances

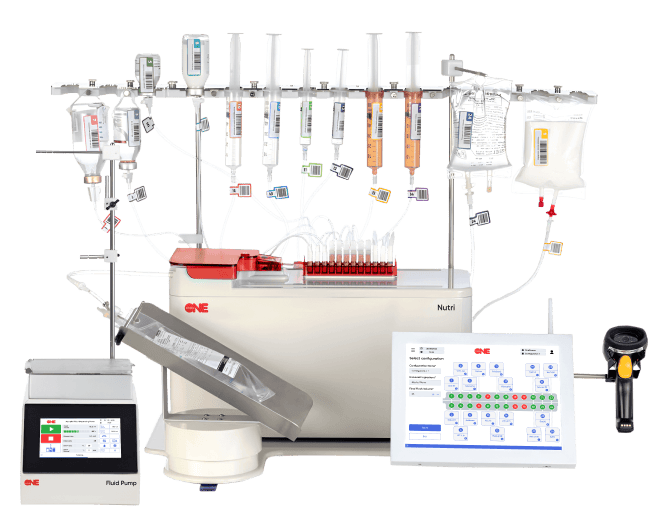

OneScreen Nutri

- Safe and secure system for input and output of drugs

Safe and secure system for input and output of drugs

- Ordering Errors

- Patient Safety

- Compounding Errors

- Traceability

- Manual Addition

- Workflow Speed

- Drug Waste

- Flexibility

- Needle-Based Injurie

- Compliance

- UV Light Effects

- ROI

- Touch-Contamination

- Quality Assurance

- Increased traceability

Increased traceabilit

- Improved quality

Improved quality

Completely automated solution for TPN units

OneScreen Pump

OneScreen Software

Compounding System

OneScreen Software Solution for TPN Unit

TPN Order Entry and Calculation Software

- Simplified order entry

- Simplified order calculation

- Drug incompatibility risk prevention

- Transcription error prevention

- Nutritional and ion-based assessment and summary

- Custom-designed pre- and final bag labels

- Multiple ordering methods ( kg/ml/% etc.)

OneScreen Turnkey Solutions

Turnkey prefabricated chemotherapy units

Provide efficient and cost-effective solutions for quality oncology care in the country

Provide efficient and cost-effective solutions for quality oncology care in the country

OneScreen Prefabricated Chemotherapy Unit

Infusion Room

Our units feature a comfortable infusion room with chairs, syringe and infusion pumps, and a relaxing atmosphere to help patients feel at ease during chemotherapy treatments.

Nurse Room

Cleanroom

Each unit includes a designated room for nursing staff, equipped with essential medical equipment to address emergencies and provide ongoing care during treatments.

There's a cleanroom with a negative pressure environment to ensure safe preparation of chemotherapy drugs in compliance with EU standards.

OneScreen Modular Cleanroom Solutions for Chemotherapy Compounding

Panels

60mm sandwich-type panels that can be easily cleaned using antiseptic agents. High-density polyurethane rigid foam is injected between two PVDF-coated white heat-enamelled steel plates. Hygienic joints with resistance to scratches and chemicals. Easy-to-clean rounded corners.

Ceilings

Pass-Boxes

Finishes

Light Fittings

Floors

Windows

Doors

Automation and Control

HVAC and Filtration

Sturdy and strong walkable ceilings for safe and easy access to mechanical systems without disrupting the cleanroom environment. Supports a wide variety of mechanical systems, lighting, sprinklers, HEPA filters, utilities, and small equipment.

- Available in static and dynamic types

- Dynamic type with 500 m3/h or more airflow, passed through H14 Hepa filters

- Interlock system to provide the best workflow and air quality Stainless steel material in inner and outer surfaces

- Acrylic window doors for a clear view of the internal chamber

All inner and outer corners have PVC or aluminium profiles sealed with silicone after assembly with oval surfaces that are flat and easy to clean.

Airtight-type lighting fixtures that can be changed from within the cleanroom. Specific design and positioning based on the device layout, staff and material flow inside the clean room.

- Hygienic type with resistance to scratches and chemicals

- Can be applied as PVC or Epoxy according to customer preference

- Flush type with the same thickness as doors and walls

- Bonded and sealed to an aluminium frame with tempered glass

- Sealed with silicone caulk

- Positioned per customer needs

- Interlock systems provide the best workflow and air quality

- PVDF coated hygienic surfaces are put on both sides

- Magnetic safety lock with password protection

- Optional width between 90-120cm

- Touch-screen for ease use

- Monitoring of differential pressures, temperature, humidity and particle count values for each zone.

- Management of alarms, electrical outlets, UV lamps and light fittings

- Display of airflow rates, particle count, filter occupancy, air quality data

- Stand-by mode with adjustable run timing

- Independent air treatment system for each zone with uninterruptible working in all weather conditions

- 100% exhausting of the air in negative pressure cleanrooms

- Three-stage air filtration: F5-F9 and H14 grade terminal filters

- Terminal filtration with H14 type absolute filters EN 1822

- Separate filtering for particle sizes and carbon filter options for preventing odor and gas.

Custom-built

Easily movable throughout a facility or to a remote location

Complete cleanroom capabilities

Easily movable throughout a facility or to a remote location

Complete cleanroom capabilities

OneScreen Modular Cleanroom Solutions for Chemotherapy Compounding

Panels

60mm sandwich-type panels that can be easily cleaned using antiseptic agents. High-density polyurethane rigid foam is injected between two PVDF-coated white heat-enamelled steel plates. Hygienic joints with resistance to scratches and chemicals. Easy-to-clean rounded corners.

Ceilings

Pass-Boxes

Sturdy and strong walkable ceilings for safe and easy access to mechanical systems without disrupting the cleanroom environment. Supports a wide variety of mechanical systems, lighting, sprinklers, HEPA filters, utilities, and small equipment.

- Available in static and dynamic types

- Dynamic type with 500 m3/h or more airflow, passed through H14 Hepa filters

- Interlock system to provide the best workflow and air quality

- Stainless steel material in inner and outer surfaces

- Acrylic window doors for a clear view of the internal chamber

- Custom-built

- Easily movable throughout a facility or to a remote location

- Complete cleanroom capabilities

Custom-built

Easily movable throughout a facility or to a remote location

Complete cleanroom capabilities

Easily movable throughout a facility or to a remote location

Complete cleanroom capabilities

OneScreen Modular Cleanroom Solutions for Chemotherapy Compounding

Finishes

All inner and outer corners have PVC or aluminium profiles sealed with silicone after assembly with oval surfaces that are flat and easy to clean.

Floors

Windows

Doors

- Hygienic type with resistance to scratches and chemicals

- Can be applied as PVC or Epoxy according to customer preference

- Flush type with the same thickness as doors and walls

- Bonded and sealed to an aluminium frame with tempered glass

- Sealed with silicone caulk

- Positioned per customer needs

- Interlock systems provide the best workflow and air quality

- PVDF coated hygienic surfaces are put on both sides

- Magnetic safety lock with password protection

- Optional width between 90-120cm

- Custom-built

- Easily movable throughout a facility or to a remote location

- Complete cleanroom capabilities

Custom-built

Easily movable throughout a facility or to a remote location

Complete cleanroom capabilities

Easily movable throughout a facility or to a remote location

Complete cleanroom capabilities

OneScreen Modular Cleanroom Solutions for Chemotherapy Compounding

Light Fittings

Airtight-type lighting fixtures that can be changed from within the cleanroom. Specific design and positioning based on the device layout, staff and material flow inside the clean room.

Automation and Control

HVAC and Filtration

- Touch-screen for ease use

- Monitoring of differential pressures, temperature, humidity and particle count values for each zone.

- Management of alarms, electrical outlets, UV lamps and light fittings

- Display of airflow rates, particle count, filter occupancy, air quality data

- Stand-by mode with adjustable run timing

- Independent air treatment system for each zone with uninterruptible working in all weather conditions

- 100% exhausting of the air in negative pressure cleanrooms

- Three-stage air filtration: F5-F9 and H14 grade terminal filters

- Terminal filtration with H14 type absolute filters EN 1822

- Separate filtering for particle sizes and carbon filter options for preventing odor and gas.

- Custom-built

- Easily movable throughout a facility or to a remote location

- Complete cleanroom capabilities

Custom-built

Easily movable throughout a facility or to a remote location

Complete cleanroom capabilities

Easily movable throughout a facility or to a remote location

Complete cleanroom capabilities

Local Capacity Building

- Complete solution

- Equipmen

- Building

- On-site software platform

Scalability

- Unit could be easy replicate

- Deployed in multiple locations across the country, providing greater access to quality cancer care for everyon

Quality and Safety

- Validation of modules at the manufacture

- Construction site safety

- Low environmental impac

- Quality management control at all stages of project implementatio

Rapid Deployment

- Quick assembling

- Fast installation

- Mobilit

- Flexible and easily-adjustable to changing healthcare priorities

Traceability

- Lower construction costs

- Fewer subcontractors

- Fewer construction workers on the sit

Compliance with EU standards

"OneScreen Chemo units meet EU regulations, ensuring the highest quality of care and safety for patients and healthcare staff

- Efficient drug distribution

- Efficient drug usag

- On-site platform for cancer drug management

Traceability

- Job opportunities for healthcare providers

- Job opportunities for local construction workers

Smart Technology

- Contribution to the economic development of the country

OneScreen Benefits

For Patients

- Access to high quality healthcare

- Safe and accurate drug administration

- Access to innovative and cost-effective solutions

For Healthcare Systems

- Increased quality and productivity of the labor

- Compliance of the treatment with the doctor's prescription

- Increased quality of cancer drug management

For Governments

- Reduced drug waste

- Reduced cost of oncology patients treatment

- Reduced cost of chemotherapy units construction

- Greater access to high quality healthcare for everyone

Phone

Email

Address

Contacts

UID CHE-484.560.933 Kanton Zug

Global Presence